Are You Positive? PC Systems

ShopTalk - June 2018

This month’s ShopTalk will take the reader deep into the mysterious world of PC (positive control) aircraft systems and break down the components and how the system works. This will lead us to the troubleshooting process of getting this system to work properly.

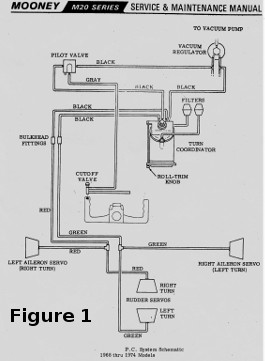

Most of our pre-1977 Mooneys originally came with a PC system as a wing leveler, a poor man’s autopilot.  This system, manufactured by Brittain Industries, is powered by vacuum pressure that passes through the turn coordinator to a pilot valve located behind the pilot’s instrument panel along with four rubber‑cupped vacuum servo cans and a thumb button (cutoff valve or switch) in the pilot’s control wheel yoke. For a schematic overview, see Figure 1.

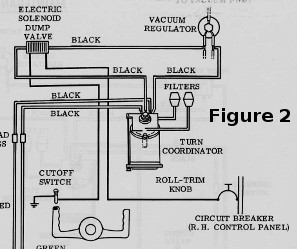

This system, manufactured by Brittain Industries, is powered by vacuum pressure that passes through the turn coordinator to a pilot valve located behind the pilot’s instrument panel along with four rubber‑cupped vacuum servo cans and a thumb button (cutoff valve or switch) in the pilot’s control wheel yoke. For a schematic overview, see Figure 1.  In 1977, Mooney replaced the pneumatic thumb button with an electrical switch and a remote solenoid valve (see Figure 2).

In 1977, Mooney replaced the pneumatic thumb button with an electrical switch and a remote solenoid valve (see Figure 2).

From an engineering viewpoint, the PC system is elegantly simple. The muscle to move the control surface (rudder or aileron) is the BI-706 which Brittain refers to as a servo assembly. Technically, this is not a servo but rather an actuator as there is no feedback mechanism. Still, we’ll take Brittain’s lead and call it a servo. The BI-706 consists of a 4.5-inch diameter can with a rubberized cup fitted to the open end (see Figure 3). As pressure is reduced in the can through the vacuum tube, the rubber cup membrane is pushed into the can by atmospheric pressure. A circular plate, affixed to the membrane, attaches to and pulls a cable (rudder) or a chain (aileron) to move the respective control surface.

As pressure is reduced in the can through the vacuum tube, the rubber cup membrane is pushed into the can by atmospheric pressure. A circular plate, affixed to the membrane, attaches to and pulls a cable (rudder) or a chain (aileron) to move the respective control surface.

Each aileron has one servo attached to the control arm in each wing. In the tail cone near and below the battery box are two servos attached to the rudder push-pull tube These two servos work against each other depending on how vacuum pressure is routed to them via the turn coordinator and the co-located roll-trim valve. All four servos are interchangeable. Some planes also came with a servo on the retractable step. This servo has the same design as the others but has a longer stroke and a larger diameter - more force. Therefore it is not interchangeable.

A thumb button (cutoff valve) is installed on the left side of the pilot control wheel. This thumb button when depressed allows vacuum to bleed off thereby releasing the control servos’ pull on the controls. It has no effect on the step servo. If this button is removed from the yoke it allows for hand-flying with no vacuum forces on any kind hindering the pilot's input. The turn coordinator is dual powered, both electric and vacuum-operated, so an electrical failure does not affect its operation or that of the PC system.

Vacuum pressure is ported off of the vacuum regulator and directed to the turn coordinator. One line will go through the pilot valve and the other will go directly to the turn coordinator. There are 2 air filters that filter the air entering the turn coordinator. These are mounted behind the pilot’s instrument panel. We will change these filters every 1000 hrs, but back in the 70s when people smoked in their plane they were changed every 500 hours.

When a PC-equipped aircraft comes in for an annual we look for clues that the PC system is malfunctioning: Is the roll-trim knob turned full stop either direction or is the yoke button removed? When we see this it is time to ask the pilot: how well the system works, what does it do in flight?

Once we have determined the PC system needs help (and most do), we pull the top cowl and place the plane on jacks with the wheels free from the ground. Then disconnect the vacuum pump from the firewall and connect the vacuum regulator to an electric standby vacuum pump powered by a remote battery.

With the electric vacuum pump running we can determine the response of the PC system to the roll-trim knob on the turn coordinator. Typically the system biases to one side or the other and will not pull on the controls evenly, left and right.

There are a number of things that can go wrong as these systems age. The most common is one or more rubber cups on the four servos will be cracked, torn, and leaking. This causes an imbalance between the servos allowing a good servo to overpower a torn or leaking servo. If the step will not retract or retracts partially this is often a servo cup leaking also. Once in a while, we see the tubing that provides vacuum pressure pulled off the servo because the fitting on the line broke.

It is very rare to find the turn coordinator control or pilot valve causing problems in the system, but they can fail as these systems age. There are two o-rings in the pilot,s cutoff thumb button that can deteriorate and weaken operation by constantly bleeding off vacuum pressure. The rubber tubing from the pilot valve to the thumb button can crack and leak vacuum pressure where it goes into the control wheel shaft behind the instrument panel.

When troubleshooting this system on jacks, first look at the rubber items: servo cups, hoses, and the thumb button. If you question the pilot valve, then bypass it and run straight vacuum directly to the system to see if it works. If you question the thumb button then disconnect it from the pilot valve and plug that line to see how that affects the system operation.

A year ago, an M20E was in the shop for some new radios and instrument panels. Once the installation was complete, the PC system was checked for proper operation. Low and behold, it did not work at all! After repairing a broken line at the right aileron servo it still did not work. The next thing was to bypass the thumb button by capping off the line to the pilot valve, and guess what? Part of the system operated, just not completely. When the pilot valve was bypassed, the system did a hard right turn - now we are getting somewhere.

Now it is time to find out which servo or servos were causing the problem. We already know the pilot valve is FUBAR, so by bypassing it, we can troubleshoot the rest of the system. Most commonly the rudder servo directly under the battery box will be rotten and sure enough, it was. This PC system needed a pilot valve and a servo replacement.

In the 70s and 80s, one could buy just the rubber cups for the servos, but the FAA now requires repair from only an approved repair facility and so a rebuilt servo from Brittian Industries was purchased for $175. The pilot valve was also exchanged for another. When the system was tested, guess what?…. It still did not work correctly.

At this point we found the tubing going to the thumb button cracked under a clamp that secures it to the control yoke shaft just as it enters the shaft. The thumb button was also missing one of the o-rings that seals the vacuum pressure. Both o-rings were replaced.

A new test was run on the system and Voila!, it worked perfectly. When the roll-trim knob was placed in the middle position all the controls were in neutral and a roll to the right was just as fast and complete as a roll to the left. Our 48-year-old PC system was finally up and running correctly.

One thing I realized during this troubleshooting process was that no one knew anything about these systems but all were interested as to how it worked. This came as a bit of a surprise to me. See, when I got into GA as a young A&P in the 70s, I learned about these systems from all those old guys that I worked with. Well, it seems those old guys are long gone and this knowledge that they passed on to me is not being passed on to the next generation very well. It also seems that I’ve become one of those guys. It must be the aviation circle of life (Hakuna Matata). That’s why I write the MAPA ShopTalk column and have the drive to continue to write it.

I remember talking to Bill Wheat years ago about all his knowledge and passing it on in a written form. Bill started with Mooney (in the late 50s) as a test pilot, then an engineer and he knew darn near everything about the Mooney aircraft systems. However, he was not interested in writing anything down and that is a shame. Bill is long gone (along with many of those other old guys) and I am grateful he shared some of his stories about the development of the M20 line of aircraft.

Since that M20E was repaired, Brittian Industries has ceased operation and is for sale due to the death of their chief engineer. With any luck, someone will buy the company and continue to offer parts so we Mooney aficionados can keep this fleet of aging aircraft operational.

If you have questions about this or any other ShopTalk article, please e-mail me at shoptalk@knr-inc.com or call me at my aircraft repair shop, 307-789-6866. All ShopTalk articles can be read here at www.knr‑inc.com. Until next time, enjoy flying your Mooney.

=====================================