Feeling the Pressure

Mooney Pitot-static System

February 2016

As living entities here on Earth, we enjoy being surrounded by a mixture of various gases – nitrogen, oxygen, water vapor, argon, carbon dioxide and traces of a few others. This surrounding gaseous mix, of course, we call the atmosphere or just air. Without it, this article wouldn't exist and neither would you. Being aviators, we frolic in it. To frolic competently, we must measure the air. From inside the cockpit, we monitor: static pressure – altitude, rate of change of static pressure – vertical speed, molecular kinetic energy – temperature, and dynamic pressure – airspeed. The static ports, pitot tube, pressure measuring instruments and ancillary components constitute the aircraft's pitot-static system.

This month’s ShopTalk educates the reader about the maintenance and repair of the pitot‑static systems in your Mooney. Included is discussion of the relevant regulatory requirements. Let's start with the basic structure of the pitot-static system.

This month’s ShopTalk educates the reader about the maintenance and repair of the pitot‑static systems in your Mooney. Included is discussion of the relevant regulatory requirements. Let's start with the basic structure of the pitot-static system.

Since all the instruments of the pitot-static system are measuring air pressure, simple plumbing is used to deliver that pressure to the individual instruments. Older aircraft utilized aluminum tubing. With the advent of engineered plastic, nylon and polypropylene tubing became the norm.

The air pressure for the static system is sampled at the two static ports located on both sides of the empennage just behind the baggage compartment bulkhead. From each static port, tubing runs up (discourages water retention) to a T-fitting at the apex of the empennage. From that fitting, the tubing drops to the static drain valve, below the battery compartment, then forward along the left of the fuselage to behind the instrument panel. Here is where the alternate static port valve (pull to open) is located (see Figure 1 – disassembled valve showing the three o-rings). After the alternate static port there is a T-fitting to feed the blind encoder and any autopilot connection. The static tubing continues to the VSI, altimeter and airspeed, a T-fitting at each. The run terminates at the landing gear airspeed switch. Note: Prior to 1969, pitot-static system drains and the alternate static valve were factory options.

For the pitot system, ram air pressure is sampled by the pitot tube under the left wing. The pitot tubing runs behind the wing leading edge to the drain valve at the wing root (see Figure 2 – the static drain looks similar), up to the airspeed indicator (T-fitting) and ends at the landing gear airspeed switch.

For the pitot system, ram air pressure is sampled by the pitot tube under the left wing. The pitot tubing runs behind the wing leading edge to the drain valve at the wing root (see Figure 2 – the static drain looks similar), up to the airspeed indicator (T-fitting) and ends at the landing gear airspeed switch.

Each pitot-static system drain has a spring and an o-ring on a tee that the spring pushes on to make a positive seal in the drain body. The o-ring can dry out and not provide a good seal as our planes age. Paint stripping can also wreck havoc with the drains and static ports causing all kinds of leaks and clogged lines.

The alternate static port valve has three o-rings that can dry out exposing the system to cabin pressure. It's as if the port were open all the time. Also, as altimeter, VSI and airspeed instruments age, their sealed faces may leak causing issues.

Between the static and pitot systems, there are at least 30 tubing-to-fittings connections. Each is another potential leakage source. Older airplanes with a lot of changes behind the instrument panel may have pitot and static lines spliced together which can cause all sorts of problems. Some airplanes are just a mess behind the instrument panel. One can see there is no way a 40-year old plane will not have some system leaks. This is why there are maximum leakage specifications.

One is allowed a small amount of leakage in the static system as long as the entire system meets the test specifications, but what about the pitot system? As it turns out there is no specification for the pitot system or the airspeed indicator. Of course, pitot system leaks will give inaccurate airspeed indications. So why is it called a pitot-static check?

Airspeed indicators measure the difference between ram (pitot) air pressure and ambient (static) pressure. Pitot pressure is always greater or equal to static pressure. Airspeed indicators are not designed for pitot pressure to be less than static. That would drive the pointer in a negative direction and can cause damage to the indicator's helical hairspring. During testing, a large pitot system leak might allow pitot pressure to drop below static.

So what is an accurate airspeed indication? Most technicians will say, as the airspeed is run up to red line, it should calibrate to be less than 4 knots, but there is not typically a specification for this. Some airframe manufactures do provide a specification but not Mooney.

There are several Mooney Service Instructions and Bulletins (all prior to 1981) concerning the pitot-static system.

Bulletins: M20-118, M20-158, M20-167 (pitot-static drains installation) & M20‑197.

Three FARs pertain to these systems: 91.411, 91.413 and 91.217. The static system, altimeter and encoder are covered under FAR 91.411. This requires you as the owner, operating under IFR, to certify (using an certificated repair station) every 24 calendar months the altimeter(s) and encoder as per Part 43, Appendix E. Also if the static system has been opened (except for alternate static or drain valves). A major static leak may cause altitude reporting errors and would prevent the system from passing the Appendix E checks. During these checks, it is a good time for repairs to be made to both systems.

The transponder is covered under FAR 91.413 which references Part 43, Appendix F. This test, inspection and certification is also on a 24 calendar month cycle. The transponder must respond with an appropriate sensitivity and reply with a signal of sufficient strength, proper format and frequency to prevent interference with adjacent frequency bands.

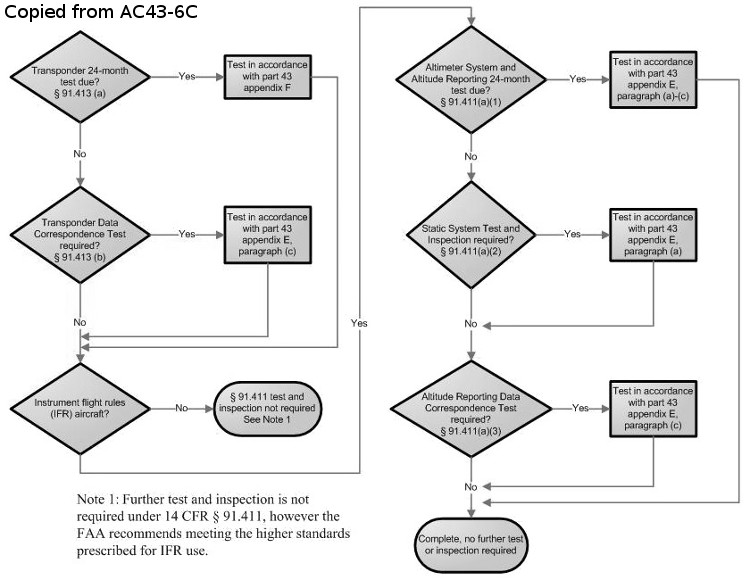

If you never fly IFR or near any airspace referred to in FAR 91.215, then you do not need to comply with any of these FARs. Unfortunately, for most of us, these places are far and few between anymore. FAR 91.411 and 91.217 go a bit farther by certifying the altimeter and encoder are within 125 feet of each other (a correlation chart is created) when run from -1000 MSL up to the maximum operating altitude of the aircraft. For this article we are only talking about non-pressurized aircraft. If you want to delve into the details of Altitude Reporting Equipment Maintenance & Inspection Practices, look up FAA Advisory Circular AC43-6C Change 1 . In the appendix of this AC is a flow chart (depicted here) which delineates the testing criteria for transponder, altimeter, altitude reporting and static system.

If you never fly IFR or near any airspace referred to in FAR 91.215, then you do not need to comply with any of these FARs. Unfortunately, for most of us, these places are far and few between anymore. FAR 91.411 and 91.217 go a bit farther by certifying the altimeter and encoder are within 125 feet of each other (a correlation chart is created) when run from -1000 MSL up to the maximum operating altitude of the aircraft. For this article we are only talking about non-pressurized aircraft. If you want to delve into the details of Altitude Reporting Equipment Maintenance & Inspection Practices, look up FAA Advisory Circular AC43-6C Change 1 . In the appendix of this AC is a flow chart (depicted here) which delineates the testing criteria for transponder, altimeter, altitude reporting and static system.

When an Aspen or Garmin PFD (primary flight display) is installed, they become part of the pitot-static system and therefore must be tested and certified when complying with 91.411 and 91.217. The altimeter must also be certified to at least the maximum ceiling of the airplane. Altimeters are typically TSO certified by the manufacture in 20,000' or 30,000' limits and have a data plate which states its maximum altitude. If a plane has a service ceiling of 22,000' you can’t use a 20,000' altimeter in it. I see this occasionally as old altimeters are replaced.

Ten years ago we did not see very many problems with the M20J and later airplanes, but as our aircraft age, we in the field are seeing more and more problems with what used to be the latest model. Proper maintenance of our aging fleet is getting to be more difficult and more expensive every day.

In the past, a basic transponder/encoder recertification was around 150 bucks. Those days are gone and now, with leaky drains, old original altimeters and encoders in old aircraft, it can cost double that or more, especially if you have to overhaul an altimeter or replace an encoder.

With the ADS-B Out mandate, FAR 91-225, just four years away (January 1, 2020), many aircraft will need new encoders due to non-compatibility with ADS-B Out hardware. It may be an expensive upgrade for some of the 60s and 70s planes that have been altered many times over the years. We shall see.

KNR continues to add past ShopTalk articles to this web site. Remember knowledge is power. Also on this web site available for download, under Documents is our Servicing Schedule spreadsheet. It's useful to track all the maintenance items to keep your plane in tip top shape. Locate in your log books the items in the left column of the spreadsheet and record the pertinent dates and times to get a good picture of what and when overhaul or replacement is due. Future ShopTalk articles will cover each item, so have your sheet filled out and follow along.