Does Your Mooney Need a Chiropractor?

May 2009

This month’s ShopTalk will take an in-depth look at the unique Mooney shock absorption mechanism.

Landing gear shock absorption in aircraft is designed to limit the dynamic stress loads that the airframe experiences during landings and high-speed operations on uneven surfaces. A properly maintained shock absorption system, as your airplane ages, results in fewer rivet replacements and fuel tank reseals.

Al Mooney designed the landing gear shock system on his airplanes differently than did Clyde Cessna, Walter Beach, Pug Piper or Lloyd Steerman. Al wanted something simple yet strong and relatively maintenance free; thus the multi-rubber disc articulating landing gear became part of the Mooney heritage with the certification of the Mooney Mite in 1948. This concept has been used in all subsequent production models.

According to Mooney historian and all-around good guy, Bill Wheat, Al Mooney discovered that Mac Truck engine mounts worked perfectly for the rubber discs on the Mooney Mite. When the M20 series was developed these discs were too small and a special disc had to be made. This landing gear shock absorption systems has evolved over the years as Mooney aircraft have become heavier, but its still basically the same system Al Mooney came up with over sixty years ago.

The active shock absorbing components of this system are the tires and the rubber shock discs. For the tires, two factors apply: correct air pressure and the proper number of plies. As Mooneys have gotten heavier with the adoption of turbo-charged engines and/or longer fuselages with more fuel capacity, tire pressures have increased and proper inflation has become more critical. Too low tire pressure can result in a flat tire during a sharp turn; the tire may roll sideways on the wheel, pinching the tube and flattening the tire. Too high tire pressure will not absorb enough energy thus transmitting the loads onto the rest of the system. The shock discs can’t absorb it all so the wing spar (meaning your fuel tanks) absorbs the energy.

The first maintenance procedure may seem simple and obvious, but it is critical; maintain proper air pressure in all three tires. Mooney aircraft have different air pressure for the nose and the main tires along with differences in pressure between most models. Use the tire pressure based on your model's Pilot's Operating Handbook requirement. Don’t use another Mooney model's tire pressure.

Airplane tires and tubes are developed and built to meet a military specification. The tubes, until recently, were made of natural rubber which tends to seep air under certain climate conditions. This is why, on many aircraft, tires will have to be frequently serviced with air. Within the last ten years, tubes of synthetic rubber have become available which are and less susceptible to air seepage. Needing less servicing, these synthetic rubber tubes are a worthy investment when changing a tire.

The tire and axle articulate to apply pressure to and compress the rubber shock discs when the weight of the airplane is on them. The rubber shock discs and the vertical stem these discs fit on, along with the collar and a bolt, keep the assembly from falling out when the plane lifts off the ground and also provides some no-load compression.

On each landing gear, between the articulating arm and the stack of discs, are three grease fittings that should be greased every 100 hours or at each annual, whichever comes first. At this pivot point are steel bushings that must move freely for the gear to work correctly. Above this point are the rubber shock discs. Earlier aircraft (pre-1965) had four discs on the nose and five on the mains. Since about 1970, these discs became unavailable so replacement is not possible. Mooney offers a kit to convert older aircraft to the current system of three discs on the nose and four discs on the main.

All Mooneys built after 1965 will have the current system. Reference Mooney service bulletins M20-139A and M20-161 to retrofit early aircraft; replacing Firestone discs with the current Lord discs.

Generally, the heavier the airplane the higher the tire pressures and the shorter the useful life of the main gear discs. All Mooneys use the same Lord disc, so, on heavier models, the compressive force is greater. Also, if the plane sits around a lot, the discs will sack out sooner than a plane that flies regularly and exercises the discs. When your Mooney transforms from a ground vehicle to an air vehicle the landing gear discs get a chance to expand while in the wheel well.

The M20 service manuals up though the K model call out measurements for the main and nose gear collars when the aircraft is setting on the ground. I have found that airplanes that sit outside will lose the elasticity in their rubber discs in less than ten years and the discs will need replacement regardless of measurement. Because these discs are rubber there is a certain amount of resiliency in them when new. As they age, the elasticity is lost and they become just a hard rubber puck that absorbs very little energy, even from normal landing impacts.

When a plane is hangared and out of the weather (not a shade hanger) the discs last a little longer but all the above elements must be taken into account. On the heavier Bravo, Ovation and Aclaim, it is not uncommon to replace the main discs every three to five years. On all Mooneys, typically the nose discs are more adversely affected by solvent and oil on them more than by the weight of the aircraft. When kept clean, the nose discs usually last longer than the main gear discs.

When a plane is hangared and out of the weather (not a shade hanger) the discs last a little longer but all the above elements must be taken into account. On the heavier Bravo, Ovation and Aclaim, it is not uncommon to replace the main discs every three to five years. On all Mooneys, typically the nose discs are more adversely affected by solvent and oil on them more than by the weight of the aircraft. When kept clean, the nose discs usually last longer than the main gear discs.

So how should you determine if your plane needs discs? First peruse your airframe logbook(s), go backwards from the last entry and look for a logbook entry that indicates when (what date) the discs were last changed. Were both the nose discs and the main discs changed? What was actually done? If a logbook entry can't be found, go out to the plane with a rag and some liquid detergent to clean and examine the discs. Each disc should have a date of manufacture stamped into the rubber next to the part number. This will give you a rough idea of how old they are. If you still have the old Firestone discs, plan to update to the new system.

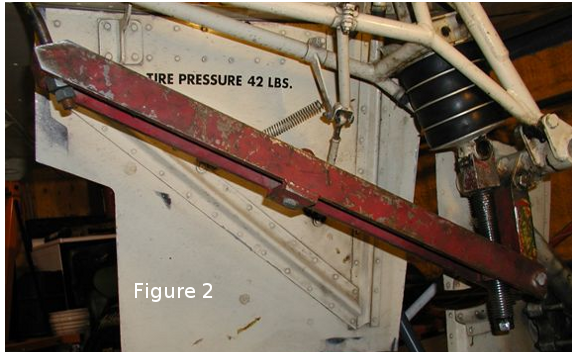

Figure 1 compares a stack of new discs with some used discs. The new discs are visibly taller than the used (ten years old) stack. The unseen difference is in the elasticity. When changing discs, two special tools are used. Figure 2 shows the tool used on the main gear to remove and reinstall the discs. A different tool is used for the nose gear.

Figure 1 compares a stack of new discs with some used discs. The new discs are visibly taller than the used (ten years old) stack. The unseen difference is in the elasticity. When changing discs, two special tools are used. Figure 2 shows the tool used on the main gear to remove and reinstall the discs. A different tool is used for the nose gear.

When replacing the nose gear discs, close attention must be taken as to how the nose gear is shimmed to the airframe because the entire nose gear must be removed. Mooney installs shims on either side of the nose gear retract pivots to facilitate proper installation of the nose steering horn as it is pinned in place to the engine mount, due to manufacturing differences. After reassembly, if the steering horn binds, the steering horn and/or the pin on the engine mount will prematurely wear out. Either of which is expensive to fix.

Another important consideration, especially on earlier planes up through the J model is to verify compliance with Mooney Service Bulletin M20-202, Nose Steering and Tracking. Many Mooneys have been damaged as they darted off the runway at high speed and into a ditch because this bulletin was not accomplished. If the nose gear discs are changed, verity your aircraft is in compliance.

To budget for this job, plan for five or six shop hours to replace both main gear discs. Currently discs cost about $60 per disc; eight discs for the mains (four per side) for $480 for the discs. During an annual, your airplane has to be on jacks, so that’s a good time to have the discs changed. If your mechanic encounters a problem with a tire hitting the gear actuating rod in the main gear wheel well, Mooney offers different collars for the main gear. These collars are drilled to place the wheel farther back in the wheel well providing clearance for the tire against the main gear actuating rod when the gear retracts.

The three nose gear discs (about $180) will take four to five hours to replace because both side panels next to each landing gear door and the doors must be removed. The complete nose gear assembly must come out of the plane. If the upper truss is dented (more than 1/32”) from over-steering, it must be replaced at this time. A new upper truss from Mooney which includes steering stops is about $1,600. A rebuilt one can be purchased for around $600 on an exchange basis if yours is repairable.

As you can see, disc replacement is not a cheap experience; mains at about $1000 and nose gear at about $600 (if the truss is dent free). Nevertheless, this is still a lot cheaper than replacing rivets in the fuel tanks or otherwise repairing the fuel tanks because the discs are so old they have no elasticity left in them. So check the age of your landing gear discs and budget for their replacement when needed, during an appropriate annual.

As always, if you have a question about this article, you may contact me at my aircraft repair shop, 307-789-6866 or via e-mail. Until the next ShopTalk, enjoy flying your Mooney.