Side Window Replacement

ShopTalk

November 2007

By Kerry Mcintyre

The December 2006 ShopTalk article took our readers through the step-by-step process of replacing a windshield of an M20J or newer aircraft. This month’s ShopTalk will walk the reader through the side window replacement of these same aircraft. Prior to the M20J, the windows were mounted differently, with just screws.

The first step is to remove all the seats and the interior sidewall panels that surround the windows. The headliner will not need to come out but this is an excellent time to refurbish it by cleaning and repainting or covering it. Removing the panels exposes the aluminum braces that hold the window in its frame. Each window, with the exception of the door, has braces on all four sides. The door window has braces top and bottom with clips on the sides. Before removing the braces, mark them so they can be reinstalled in their exact position as each brace is individually drilled to each location. For instance, the bottom brace removed from the right-rear window will not properly line up with the bottom position of the left-rear window.

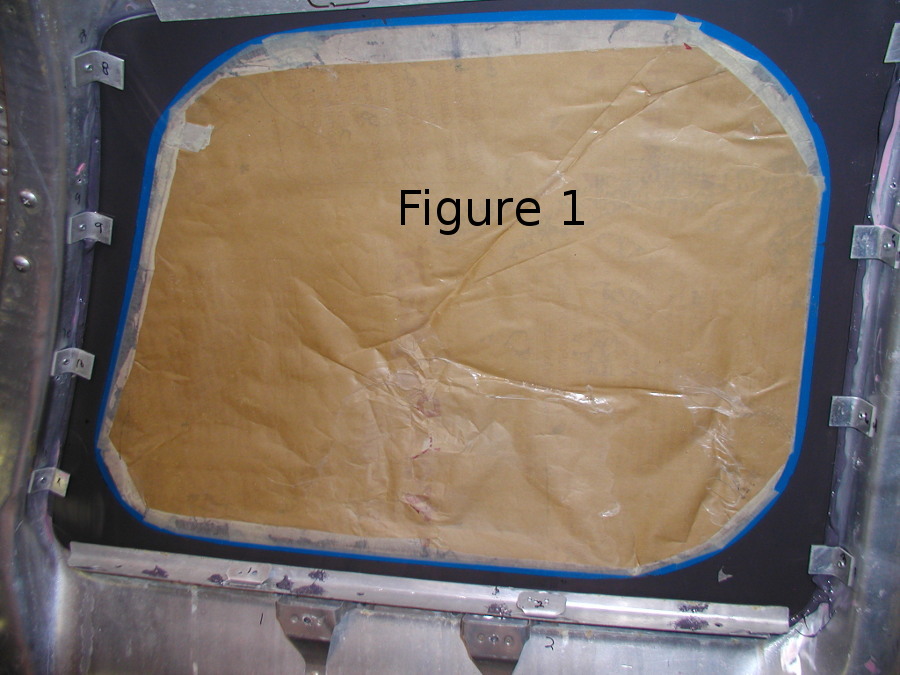

Some aircraft have flat strips of metal that are attached to these braces. These strips accept the window molding screws so mark them also. You will soon be cleaning the braces of excess window sealant so mark the positions indelibly. See Figure 1.

By now you should have all the window braces removed and marked as to both location and direction. To break only the adhesion of sealant but not bend the sheet metal around the windows, slowly push each window into the cabin. Once the windows are removed from the airframe the next job is to clean the old sealant from the sheet metal.

The fuselage skins are thin, so don't get too aggressive pushing the windows out as you might damage the fuselage skin or possibly the cabin roof. We use a razor blade to get the bulk of the old sealant off and a 3" rotary Scotch-Bright pad to remove the rest. This process creates a mess of fine powdery dust, so cover the interior panels, floors, controls and instrument panel. The rest of the material can be wiped up or vacuumed out.

As we did with the windshield replacement (link to article), remove all the paper and plastic (save as much as possible for re-use) from your new windows and inspect them for flaws. By looking through the window at an 8-foot fluorescent light (or another highly visible straight line) you can tell if the window has any aberrations. If the light tube looks straight, then the window is okay, but if it looks bent, get another window to install. See Figure 2.

The remainder of this installation requires considerable handling of the new windows. To protect them from scratching, re-cover with the saved paper and plastic, both sides leaving 3" showing around all edges. Because no two airplanes are made alike, each window must be custom fitted. Don't be surprised if a little trimming is needed for each window. A 3" rotary cutoff wheel and 3" sander work fine for this.

Once the side windows are trimmed and fitted, temporarily install them using #30 Clecos (copper colored) to hold the frames in place. Now you can mask off the outside to match the airframe. It's important to mask the outside of the window right up against the edge of the airframe so that any tank sealant that squeezes out as you push the window into place will end up on the masking and not on the window. Also, mask the area of the airframe around the window to protect the exterior paint and facilitate clean-up of the squeezed-out sealant. This is also a good time to do any interior masking. By masking everything off properly now it will save you a tremendous amount of clean up time later. We use blue fine-edge pin-stripe tape on the window against the airframe and regular masking tape on the rest of the window. After masking, put alignment marks on the window and the airframe so, when you place the window with sealant on it, it can be re-positioned to its exact location.

Two pints of low-adhesion tank sealant is needed for four windows, but mix one pint at a time. Start with the back windows. Place a bead of sealant, about the diameter of your index finger, all around the outside border of each window. Line up the alignment marks and place each window, again using #30 Clecos to hold the frames in place. The excess sealant should squeeze out onto masking on the window and airframe.

Make sure there are no gaps between the airframe and the window. If there are gaps, fill them with excess sealant as necessary. It is more important to have excess sealant squeeze out onto the airframe than to be filling gaps from the outside of the airplane. Use plenty of sealant on each window. Once the windows are installed and the braces are Clecoed in place, the braces may be riveted using Avex 1601-0410 pop-rivets as the Clecos are removed, one at a time. After all the riveting is done, apply a small dab of sealant to cover any rivet heads that may allow water to leak into the steel tubular fuselage. This is a necessary item to be completed, don't forget to do this. The door and pilot’s windows are installed in the same manner as the back windows.As you rivet, make sure to clean up on both sides of the window. A small spatula or flat-blade screwdriver may be used to remove and flatten any excess sealant. Let the sealant set up a bit overnight and then remove the masking. Allow the sealant 72 hours to fully cure. If you have masked the windows and airframe properly, there will be very little cleanup.

The pilot's storm window should be installed after the pilot’s larger window is in place. This is due to the tension that the installed window may be under. If you drill and locate the storm window with the pilot's window removed, the storm window may not fit properly once the pilot's window is installed. When installing the pilot’s storm window, use a small piece of wood as a backstop for the holes drilled into the pilot’s window and storm window. Take your time and drill pilot holes first before drilling the final size holes needed for the hinges. Make sure the hinge screw fits loose in the hole, this will allow room for the window to expand and contract as the temperature changes, and not crack the window at the hinge.

Reinstall all the interior panels and screws, seats and seat stops. Plan about four days downtime to remove, clean, trim, prep, mask and reinstall four windows. The fuel-tank sealant we use is low adhesion with a 72‑hour cure time.

As with this or any other ShopTalk article, if you have questions, feel free to e-mail me, shoptalk@knr-inc,com or call me at my aircraft repair shop, 307-789-6866.

Until the next ShopTalk, enjoy flying your Mooney!