PRECIOUS MOMENTS - DETERMINING BASIC EMPTY WEIGHT & CG

ShopTalk - March 2016

As we age it’s not uncommon for most of us to add a couple of extra pounds. After weighing airplanes for the last 10 years I have concluded that our Mooneys are not much different than us when it comes to aging and weight gain.

Way back in time, airplanes were weighed using calibrated mechanical scales under each wheel to determine the weight on each wheel. Today, most of us doing this kind of work have electronic scales that use load cells to determine the actual weight at each wheel. So why is it important to have an accurate empty weight of our airplane?

By knowing the correct basic empty weight (BEW) of our airplane one can determine an accurate maximum load of fuel, passengers, and baggage as not to exceed the manufacturer's maximum takeoff weight and center of gravity (CG) envelope. When your airplane is on the scales an accurate BEW and CG are determined.

If one exceeds the forward or aft CG limits of the plane they are flying, it can be disastrous in the form of not enough nose up trim or a departure stall on takeoff. Additionally, aircraft exceeding TOW and CG limits may exhibit stability problems and compromised stall recovery. In fact, anything that can sustain controlled flight, whether it is a bee, bat, bird, beetle, Boeing, or Bravo, must conform to weight and CG limits.

A few years ago, KNR was applying to the FAA for an STC and was doing some flight testing with our plane in the temporary experimental category. The FAA required that we had completed a measured BEW and CG along with a correct equipment list before any flight test occurred; historical numbers would not do. We were expected to take off at an airport below 2000 feet MSL on a day above 100 degrees and climb at the maximum angle of attack (full power) with maximum aft CG loading and 10% over the manufacturer's gross weight limit! During initial certification, aircraft are tested to just unsafe limits, then these limits are adjusted for reasonable margins. Our flight test provided data to the FAA that our oil cooler relocation kit worked, but as one can see we were required to operate in the most extreme conditions possible. When you're flying at weight and CG limits it is good to know that your airplane will function safely.

So, basic physics should compel you to follow weight and CG limits, but what about legal requirements. What FARs compel us? None! There are no Part 91 FARs that reference weight and balance. However, airworthiness requirement comes from FAR 91.7, and 91.9 requires a Flight Manual (POH) which contains the manufacturer's weight and balance criteria. Lastly, the Standard Airworthiness Certificate (FAA Form 8100-2, shown below) ties everything together by stating, in Item 6. Terms and Conditions, that “maintenance, preventive maintenance, and alterations are performed in accordance with Parts 21, 43, and 91 of the [FARS]”, etc.

All certified airplane manufacturers have a published way to complete an accurate weight and balance, but without a correct equipment list, future weight and balance accuracy would be in question. Therefore, one of the first things looked at during an annual is the equipment list in the Pilot's Operating Handbook (POH) to be compared to what is actually installed. This simple check gives the mechanic a glimpse into the accuracy (or inaccuracy) of the weight and balance. Yes, having an accurate weight and balance is part of your airplane's annual. If your equipment list does not match your plane, we are off to a bad start.

So now that we have discussed the basics, let’s get into the actual job of creating a new BEW and CG for your Mooney. The first thing we do is drain all the fuel from the plane, and then we add in unusable fuel equally into each fuel tank. Most airplanes require maximum oil in the engine per the dipstick. You must follow the airplane's maintenance manual or in most cases the POH as to what the unusable fuel is or the maximum oil is. The FAA also has an acceptable way to determine weight and balance in their publication AC 43.13-1B chapter 10. Some shops like to weigh the plane with full fuel, then mathematically deduct the fuel weight out, but this is not (in my opinion) an accurate way of weighting a Mooney.

Because Mooneys have a wet wing, the outboard part of the fuel tank goes beyond the filler neck. It is used as a place to capture air pressure which helps maintain a positive head pressure to the fuel pumps. Owners of a Bravo, TN, Ovation, or Monroy long-range tanks can attest that one can add another few gallons of fuel by gently rocking the plane and letting it sit a few minutes, then topping off the tanks again. This is possible due to the design of the wet wing and the wing dihedral. I call it burping the tanks. This situation makes it difficult to determine if the tanks are completely full.

Once the tanks are drained and the unusable fuel amount is added back into each tank, the fun begins. The airplane is raised on jacks and the scales are placed under each wheel. Between each main wheel tire and scale is a metal plate with chocks welded to it to prevent the airplane from rolling off the scales. The weight of the chock assembly must be deducted from the scale reading, or if possible, with only that assembly present, zero the scale.

Mooneys, resting on their wheels on level ground, are not in the (pitch) level attitude for calibrating CG. For level attitude, the nose wheel needs to be about three inches lower than the mains. To accomplish that at KNR, each main wheel scale is stabilized on top of thick concrete pavers (See Figure 1). The jacks are now carefully removed. Before recording the scale readings, the airplane must be leveled in both directions using the manufacturer's established level points. Leveling is fine-tuned by adjusting individual tire pressure.

Once the airplane is level and all its weight is resting on only the scales, a reading is written down. A plumb bob and tape measure are used to mark and measure chalk lines on the floor directly below established points on the airplane as per the airplane manufacturer's or FAA requirements (either is acceptable). Why not just use the aircraft's dimensions? Since the aircraft's BEW and CG are calculated from the individual weight on each wheel, the relative position of those wheels is important. Especially for Mooneys, those positions are not fixed. Mooney's landing gear utilizes trailing arm technology and the landing gear donuts have different degrees of flex, depending on age. Ergo, the wheel geometry is variable.

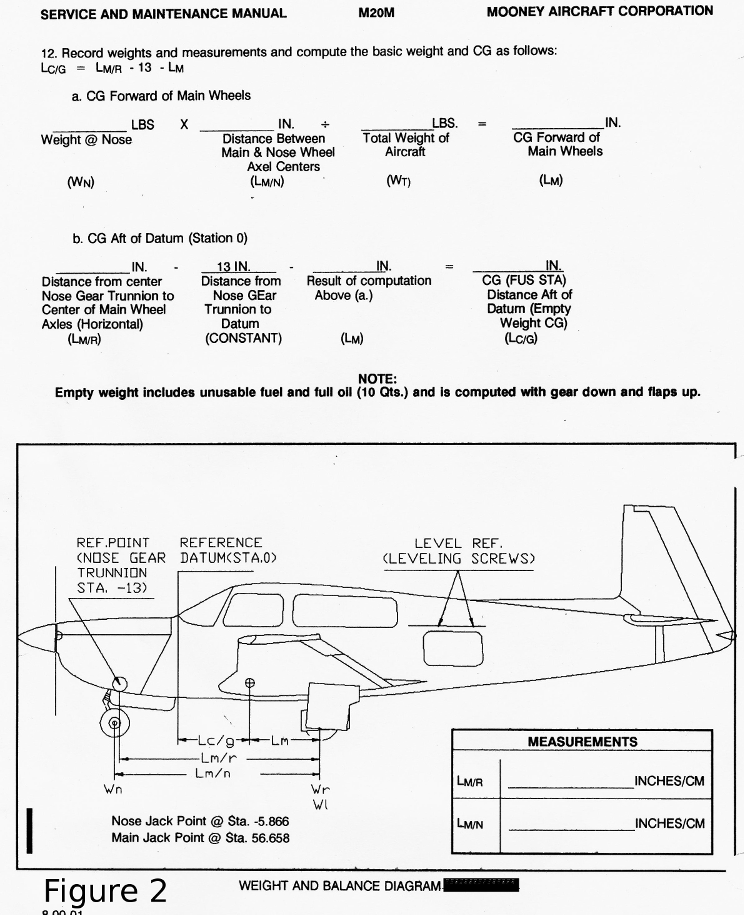

Reference Figure 2, copied from the Mooney M20M Maintenance Manual. There is a similar diagram in each model's POH. Following the procedures from the Mooney POH, the CG is calculated with reference to the main wheels, then adjusted to the nose gear trunnion and finally to Reference Datum, effectively the front surface of the top of the firewall. All of these measurements are plugged into a formula that the manufacturer or FAA has approved for that airplane and a BEW and CG are calculated. The useful load can now be determined by simply subtracting the BEW from the published maximum gross weight of the airplane being weighted.

After all the measurements are completed, the airplane can be removed from the scales. A correct equipment list must be created (most are not correct) and dated the same date as the weight and balance date so no one will question the accuracy of the work completed. This work must be done by a certified airframe mechanic as they will have to update and sign off an entry in the airframe logbook and the POH.

It is acceptable to do a calculated weight and balance, but with all the avionics changes going on in the industry these days, it is a better practice to just have the airplane reweighed. Here is a link to a previous article (March 2005) titled Weight? Wait. Don’t tell me! which discusses specifics about why an aircraft might weigh more than what's calculated.

If you have questions about this or any other ShopTalk article, please e-mail me at shoptalk@knr-inc.com or call me at my aircraft repair shop, 307-789-6866. All ShopTalk articles can be read here at www.knr‑inc.com. Until next time, enjoy flying your Mooney.

========================================================================