Mooney Parking Brake Problems - pre-1979

ShopTalk - June 2020

Continuing the aging Mooney theme, ShopTalk will cover common parking-brake problems in earlier Mooney aircraft. For a few articles, we are focusing on the small parts and ancillary systems that are becoming difficult to maintain due to a dearth of replacement parts.

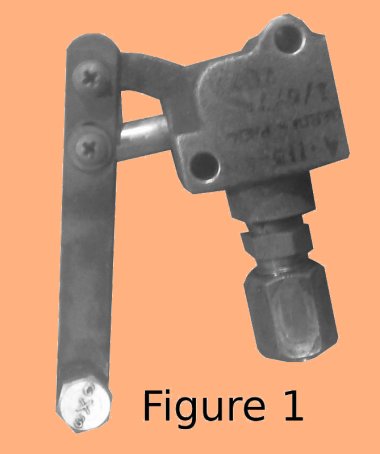

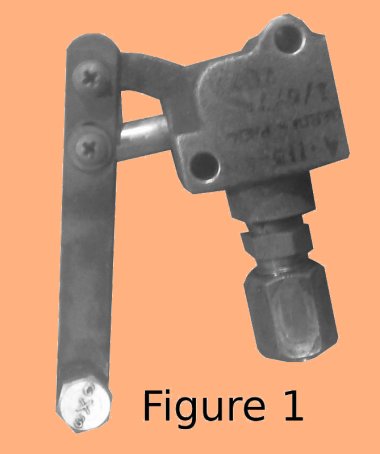

In 1979, Mooney stopped producing airplanes with the Gerdes parking-brake valve (Figure 1). Mooney subsequently used Parker-Hanifin components (also known as Cleveland) for the master cylinders and parking-brake valves. The Parker-Hanifin parking-brake valve is located just under the pilot’s seat, in the belly, mounted to the floor. This location required a longer actuator cable assembly along with changes to the brake lines that feed fluid to the wheel cylinders.

The original Gerdes parking-brake valve was normally under the pilot's rudder pedals mounted to the bottom of the floor. The fluid reservoir is located in the tail cone above the battery, but earlier aircraft had this valve and its reservoir mounted just under the brake fluid reservoir on the firewall in front of the pilot.

The Gerdes valves and the Parker valves are rebuildable with standard MS28775 series O rings. Unfortunately, the Gerdes valve bodies are wearing out from usage with some so worn that rebuilding them is no longer an option. These valves are very simple and reliable and until recently, we have not needed to replace one. However, that one replacement is a harbinger of future failures.

Some typical symptoms of a worn-out parking-brake valve are:

1) You are constantly getting air into the brake system even though you have rebuilt or replaced the master cylinders and wheel cylinders.

2) The parking-brake valve will not stop leaking or won’t hold pressure in the lines.

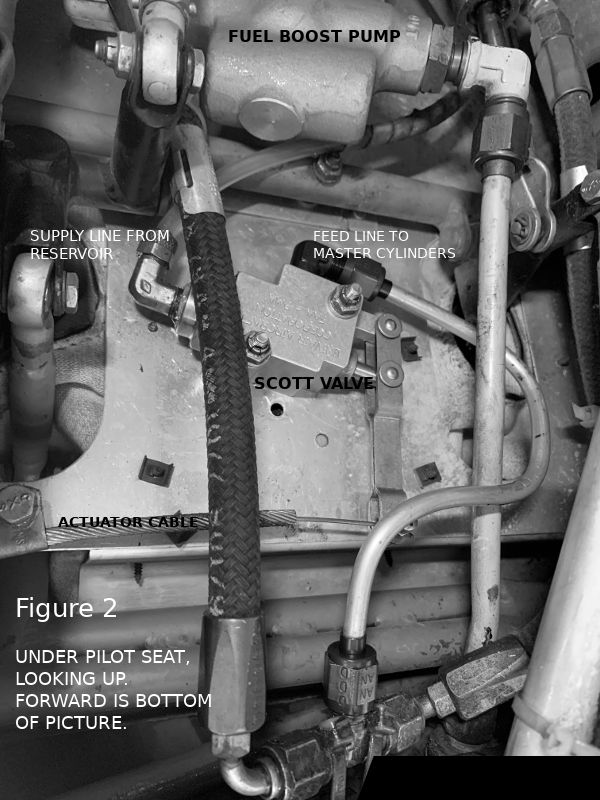

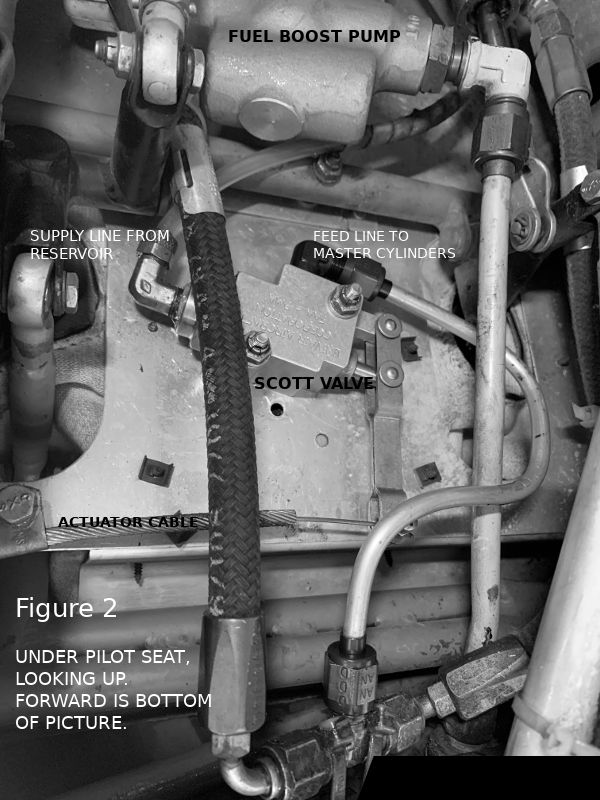

When you look at Figure 2, you can see the location of this valve under the pilot’s rudder pedals (M20J) but here we have replaced the obsolete Gerdes valve with a Scott 4500-A1 parking valve.If Mooney had a retrofit kit to upgrade this system you would have to use it, but Mooney has no such kit so the Scott valve is your only choice.

The first thing one will find is the Scott valve looks similar but is not orientated for the same fluid flow direction as the Gerdes valve was. This makes the replacement job a bit more difficult as you will have to fabricate a new output line. First, position the Scott valve so that both the feed line and the actuator cable will reach and are aligned (again Figure 2).

Once you have secured the new Scott valve to the floor and hooked up the feed and exit lines, the system must be back-bled through each wheel cylinder. An operational test of the parking-brake valve and a test of both brakes for proper operation is the next item to complete.

Once you are sure there are no leaks and the brake reservoir is full, the access panel can be closed. The plane is returned to service by an airframe-rated (or better) mechanic. A logbook entry is required for the part and the work completed. No, the pilot is not authorized to do this.

A 337 form is not needed as an unsupported, unavailable part is being replaced with an FAA PMA approved current production part. An installation STC is not needed. Advisory circulars 23-27 and 43-18 state that one can substitute or fabricate parts if the manufacture has no options for replacement. There are other parking valves on the market but the Scott is the only FAA PMA manufactured part as far as our research could find. Replacing with a PMA part is robust solution given this scenario.

If you call a Mooney dealer, they will tell you that the Parker valve is a direct replacement but because it will not fit in place of the original Gerdes valve it is not a direct replacement. If Mooney had a kit to upgrade the old Gerdes valve to the new Parker valve it would come with a factory drawing, parts and parts list with instructions as to how to complete this job. That is the usual path to returning the aircraft to service.

It is not getting any easier to keep these 42+ year-old airplanes airworthy without the help of the factory that originally built them. I can’t imagine what someone with a Curtis Robin (Figure 3) has to go through to keep their airplane airworthy.

If you have questions about this or any other ShopTalk article, please e-mail me (see below) or call me at my aircraft repair shop, 307-789-6866. All ShopTalk articles can be read here at www.knr‑inc.com. Until next time, enjoy flying your Mooney.

If you have questions about this or any other ShopTalk article, please e-mail me (see below) or call me at my aircraft repair shop, 307-789-6866. All ShopTalk articles can be read here at www.knr‑inc.com. Until next time, enjoy flying your Mooney.

In 1979, Mooney stopped producing airplanes with the Gerdes parking-brake valve (Figure 1). Mooney subsequently used Parker-Hanifin components (also known as Cleveland) for the master cylinders and parking-brake valves. The Parker-Hanifin parking-brake valve is located just under the pilot’s seat, in the belly, mounted to the floor. This location required a longer actuator cable assembly along with changes to the brake lines that feed fluid to the wheel cylinders.

The original Gerdes parking-brake valve was normally under the pilot's rudder pedals mounted to the bottom of the floor. The fluid reservoir is located in the tail cone above the battery, but earlier aircraft had this valve and its reservoir mounted just under the brake fluid reservoir on the firewall in front of the pilot.

The Gerdes valves and the Parker valves are rebuildable with standard MS28775 series O rings. Unfortunately, the Gerdes valve bodies are wearing out from usage with some so worn that rebuilding them is no longer an option. These valves are very simple and reliable and until recently, we have not needed to replace one. However, that one replacement is a harbinger of future failures.

Some typical symptoms of a worn-out parking-brake valve are:

1) You are constantly getting air into the brake system even though you have rebuilt or replaced the master cylinders and wheel cylinders.

2) The parking-brake valve will not stop leaking or won’t hold pressure in the lines.

When you look at Figure 2, you can see the location of this valve under the pilot’s rudder pedals (M20J) but here we have replaced the obsolete Gerdes valve with a Scott 4500-A1 parking valve.If Mooney had a retrofit kit to upgrade this system you would have to use it, but Mooney has no such kit so the Scott valve is your only choice.

The first thing one will find is the Scott valve looks similar but is not orientated for the same fluid flow direction as the Gerdes valve was. This makes the replacement job a bit more difficult as you will have to fabricate a new output line. First, position the Scott valve so that both the feed line and the actuator cable will reach and are aligned (again Figure 2).

Once you have secured the new Scott valve to the floor and hooked up the feed and exit lines, the system must be back-bled through each wheel cylinder. An operational test of the parking-brake valve and a test of both brakes for proper operation is the next item to complete.

Once you are sure there are no leaks and the brake reservoir is full, the access panel can be closed. The plane is returned to service by an airframe-rated (or better) mechanic. A logbook entry is required for the part and the work completed. No, the pilot is not authorized to do this.

A 337 form is not needed as an unsupported, unavailable part is being replaced with an FAA PMA approved current production part. An installation STC is not needed. Advisory circulars 23-27 and 43-18 state that one can substitute or fabricate parts if the manufacture has no options for replacement. There are other parking valves on the market but the Scott is the only FAA PMA manufactured part as far as our research could find. Replacing with a PMA part is robust solution given this scenario.

If you call a Mooney dealer, they will tell you that the Parker valve is a direct replacement but because it will not fit in place of the original Gerdes valve it is not a direct replacement. If Mooney had a kit to upgrade the old Gerdes valve to the new Parker valve it would come with a factory drawing, parts and parts list with instructions as to how to complete this job. That is the usual path to returning the aircraft to service.

It is not getting any easier to keep these 42+ year-old airplanes airworthy without the help of the factory that originally built them. I can’t imagine what someone with a Curtis Robin (Figure 3) has to go through to keep their airplane airworthy.

If you have questions about this or any other ShopTalk article, please e-mail me (see below) or call me at my aircraft repair shop, 307-789-6866. All ShopTalk articles can be read here at www.knr‑inc.com. Until next time, enjoy flying your Mooney.

If you have questions about this or any other ShopTalk article, please e-mail me (see below) or call me at my aircraft repair shop, 307-789-6866. All ShopTalk articles can be read here at www.knr‑inc.com. Until next time, enjoy flying your Mooney.