ShopTalk - October 2001

As most of you know by now, most four-cylinder Lycoming engines have an FAA airworthiness directive, AD 96-09-10, against the oil pump gears. The AD should have been complied with by July 15. 2001. Update 2019: I am still finding a few that have not been fixed! Don Maxwell has done a good job of explaining the AD and how it applies to your engine in previous issues of the Log. However, I'd like to give you my thoughts on the subject and discuss a little bit about how these pumps work.

First, a little history: The very early oil pump gears were made of sintered iron. AD 81-18-04, R1 and R2 required replacement with steel‑to‑aluminum gears. About 1985, Lycoming and, later, other manufacturers started making hardened steel‑to‑steel gears and for some time both types were available. As of 1985, AD 81-18-04 R2 was in effect allowing the aluminum idler gear.

However, the latest AD 96-09-10 mandates using only hardened steel‑to‑steel gears. When you read AD 96-09-10, you notice that four separate Lycoming service bulletins are listed: 454B, 455D, 456F and 524. Depending on your model engine, one or more of these bulletins must have been completed. An approved engine shop must comply with these bulletins and would have used the steel‑to‑steel gears, but an A&P could have used either type until AD 96-09-10 was issued.

Specifically, if AD 81-18-04 R2 was accomplished with the appropriate service bulletin, then AD 96-09-10 may also have been complied with. The five-year limit to accomplish AD 96-09-10 expired on July 15, 2001. Bottom line: If your engine doesn't have a carburized and nitrided steel impeller kit installed for the oil pump (part #05K19423-S), then you are not in compliance with AD 96-09-10, and this renders your airplane not airworthy.

Wait, there's more. If your engine doesn't have the one‑piece oil pump housing body, you are required to replace it also. Another part that will probably need replacement is the oil pump drive shaft. This part has a flat section on each side to engage the oil pump impeller gear and is typically worn on the edges. If reused with the new gear, the wear will only accelerate. This drive is about $150 (as of the date this article was written, 2001) for the early engines with individual magnetos. For engines with the single-drive dual magneto, this item is over $600.

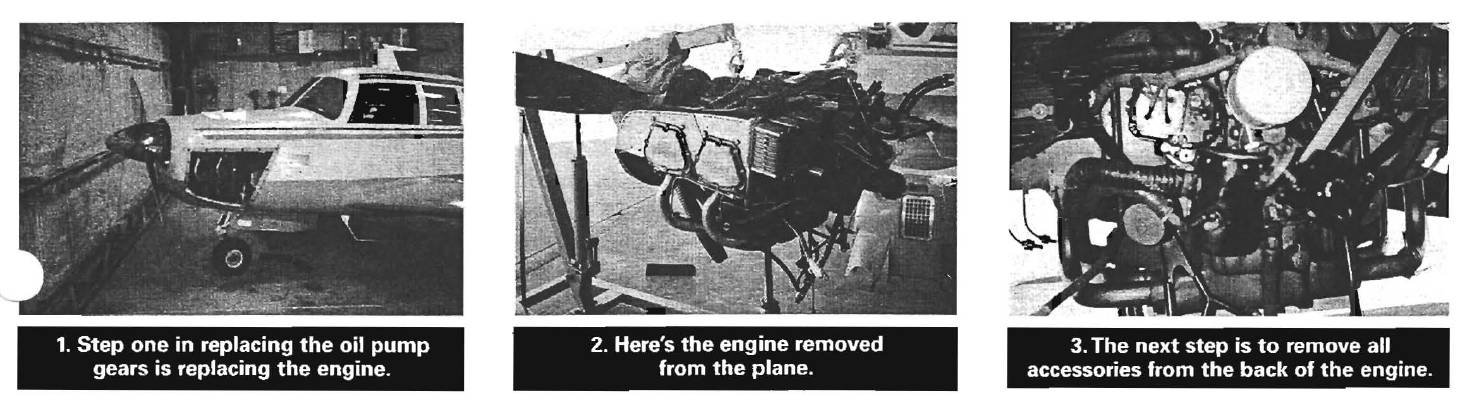

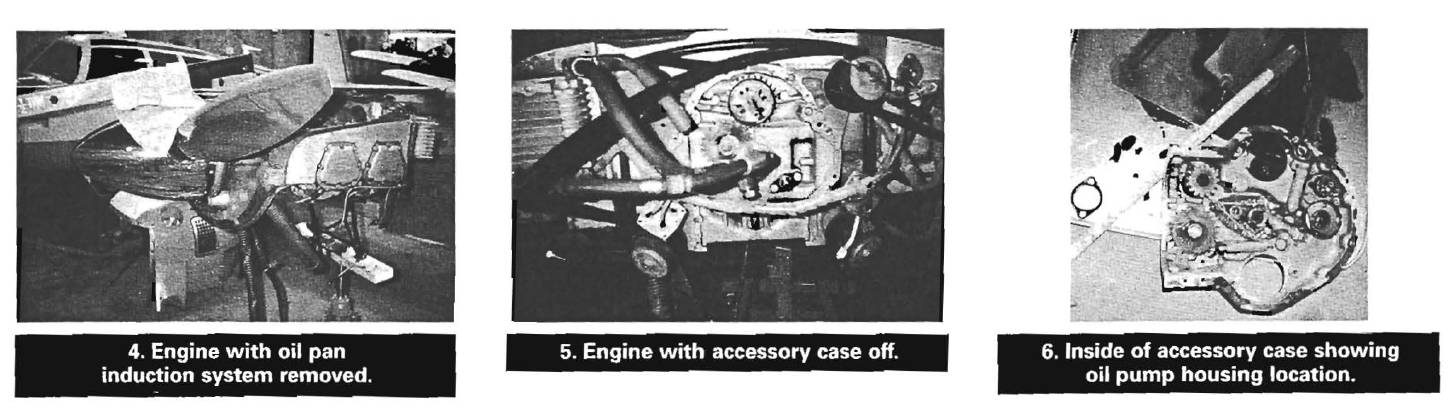

So, what is involved in changing these oil pump gears? On most airplanes, you must pull the engine out of the airframe to remove the accessory case. Once you remove all the accessories, magnetos, fuel pump, vacuum pump and on some airplanes the prop governor on the back, then you can remove the oil pan and induction system. Now, the accessory case can be removed. Inside the accessory case is the oil pump housing.

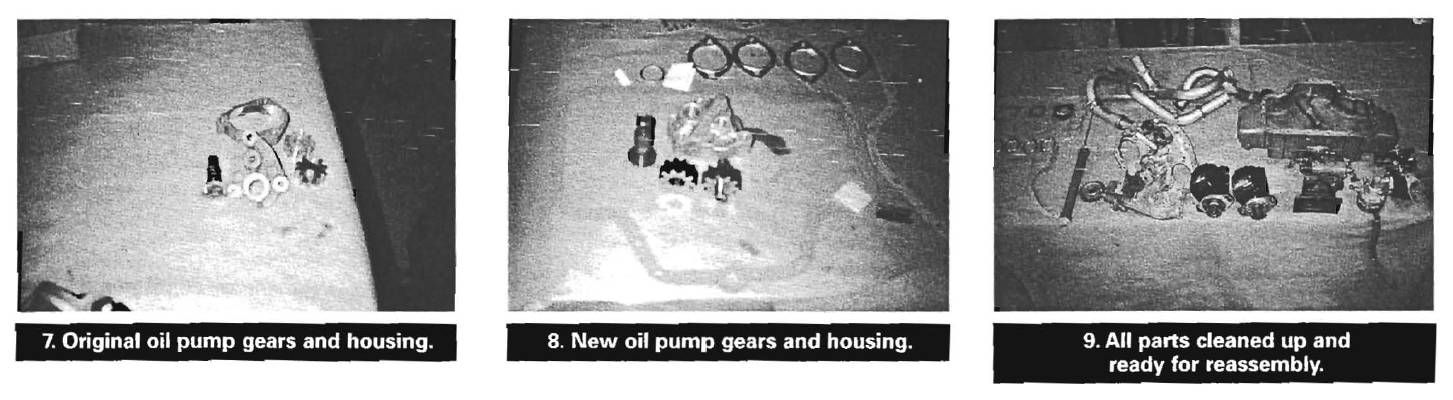

By removing the safety wire and the nuts off the housing you can extract the housing and the oil pump gears. As stated earlier, a multi-piece oil pump housing must be replaced with a single-piece oil pump housing. This part is $250 to $400. Oil pump gears purchased directly from Lycoming will cost another $400. There are other suppliers of approved oil pump gears of the same quality and typically about half the price. You will need new gaskets for the intake manifold, magneto(s), fuel pump, prop governor (if removed), oil pan, vacuum pump and accessory case. It will take a few hours just to clean all these parts and be ready for reassembly. This is not a one-day job; plan four or five days of downtime.

Since the compliance date for this AD has already expired, there is a run going on for the replacement parts. Many are on backorder. The good news is that in a couple of months, the manufacturers should have caught up with the demand and parts will be available. I anticipated this shortage beforehand and put together several complete kits for my customers.

Some additional expenses will probably occur. Anytime extensive work is done, something else needs repair or replacement. Old hoses, engine mounts, tired magnetos and other items are best replaced while the engine is being worked on. Typically, it will cost $2,000 to $3,000 just to comply with the airworthiness directive. But if you go ahead and have some other work done now, some expenses will be saved at the next annual inspection.

A quick look at the pictures that go with this article should confirm that complying with AD 96-09-10 is not a one-day scenario, so plan accordingly. As always, if you have a question about this or another article, contact me at our aircraft repair facility via e-mail: ShopTalk knr-inc.com or the old-fashion way via phone: 307‑789-6866. All ShopTalk articles can be read here at www.knr‑inc.com. Until next time, enjoy flying your Mooney.

knr-inc.com or the old-fashion way via phone: 307‑789-6866. All ShopTalk articles can be read here at www.knr‑inc.com. Until next time, enjoy flying your Mooney.